- Epoxy

- Includes resin and hardener

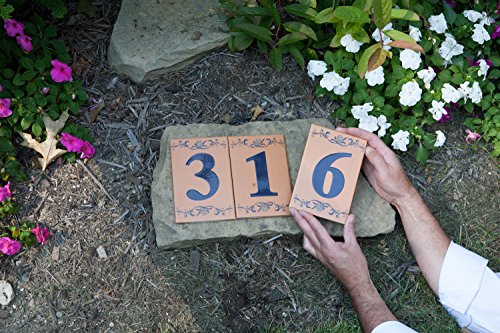

- Ideal for multi step projects such as chair assembly, Stair spindles, decks, trellises, arbors, fencing, lattice, mounting studs, stonework and laminating

- Project size bottles for use on large or multi piece jobs requiring super high bond strength

- Sets in 5 minutes

- Bonds metal, glass, ceramic, wood, many rigid plastics, china, tile, fiberglass, concrete and stone

- Can be combined with fiberglass cloth for a durable patch

- High impact resistance - won't crack when drilled

- Water resistant and does not shrink

- Two 4-Ounce bottles (8-Ounce total)

- Bonds metal, glass, ceramic, wood, many rigid plastics, china, tile, fiberglass, concrete and stone

- Can be combined with fiberglass cloth for a durable patch

- High impact resistance - won't crack when drilled

- Water resistant and does not shrink

- Two 4-Ounce bottles (8-Ounce total)

-

Information

-

Twitter

-

Pinterest

-

Youtube

-

Facebook

Calvin Parkinson

if it can't be comfortably clamped. It's strong

I cannot live without this stuff. This should be part of everyone's zombie apocalypse kit. As a dedicated handyman, inventor, and home maintenance technician (unofficial), I use this stuff all the time. It gives you just enough working time that you don't have to hold something in place too long, if it can't be comfortably clamped. It's strong, and sticks to almost anything. This 8 oz size is the bomb. It seems to have a really good shelf life, I had my last bottles for over a year.

Imran Barlass

I hated having leaks from the dual syringe variation of this ...

I hated having leaks from the dual syringe variation of this product. The 2 separate bottles solves that problem for me. The holding strength meets every need I have had thus far. I will buy again... if I ever run out.

Livia Holguin Crooks

The go-to for household use epoxy

I've used this on everything from plastic kids' toys to hidden tang knives. I also epoxied a quarter to the garage floor in 2012. It is in a high traffic area, and it is still stuck there (2018). Excellent prank- if I can pat myself on the back. It has adequate shear strength, but that depends on the surface area & material. Wood-metal, metal-metal, ceramics... the only failure I have had was epoxying a silicone slip handle on a non-stick frying pan. There was too much heat involved for that application. That particular problem was remedied by drilling a through-hole, tapping the hole, and securing the handle with a machine screw. This is the best value available. I buy little condiment cups to mix the epoxy in, and I use old credit cards cut lengthwise (into 5 sticks) to mix with. Acetone or lacquer thinner will get it off your hands, but be careful with acetone & lacquer thinner... Clean the nozzles after each use & you'll get longer use out of this product.

Angel Dimitrov

Very useful stuff

This is the most used tool in my garage. I have successfully used this Epoxy on wood, many types of plastic, metal, ceramic, brick, and glass with no problems at all. One word of caution: If you don't get the ratio quite right (should be 1:1) it might not harden all the way. Otherwise it sets within minutes and hardens after ~8 hours. Get some cheap flux brushes for application. The fumes are quite powerful, so I also recommend wearing a respirator. Another tip-- First thing I do is draw a sharpie mark on one of the caps and its corresponding bottle so I don't put the cap on the wrong bottle. If you do that, you'll never get it off. One other note on temperature: I used this to re-glue the magnet onto the back of my kitchen timer. It is stuck to the side of my refrigerator, above my gas stovetop and is exposed to some heat rising off the stove. I have noticed some yellowing of the area on the fridge around the magnet, maybe due to outgassing when the hardened epoxy is exposed to high heat. The epoxy is still holding the magnet like a champ but it did leave a slight mark on my fridge.

Kayla Regimbald

Strong bonds and good bottles that will help it to last for years.

This does make strong bonds. I'm using it for small jobs around the house, so it is going to last a long time. Fortunately the bottles and caps work well to ensure that air does not get in but it is easy to open again. So this should last for years.

Pretty Swag

Good, but goopy.

This is a good product. Everyone knows what epoxy is... but I'll add this here. It's damn goopy! GOOPY. That's right. Goopy. And STICKY! Goopy and sticky! Oh, you'll think, "i'm being very careful here not to get the goopiness all over the place while mixing it. But alas, you will FAIL. The goopiness shall envelope you and get all over your stuffs! HA! HA! HA! You can use as much epoxy as you like, but you will never, and I mean NEVER escape it's goopiness. It's coming for you.

Wendy Perez

Really great epoxy.

I use a lot glue and for a variety of situations. I first used this epoxy in the small bottles and was impressed with open time and cure rate. I get a wider working time even and bond strength is still there in a short amount of time for a 30 min epoxy. These large bottles are a better value and cleaner to use. The clarity of the epoxy is very high and takes dyes very well too. Loctite epoxy is great stuff!

Mylene Mylene

THIS PRODUCT FIXES MANY PROBLEMS!

Had a decorative decoy duck of wife's made of resin. Broke wing off. Couldn't find anything to work--until this. Solid fix. Also had a GE electric cooktop (glassfilled, I believe) that was cracked due to someone accidentally striking the edge.( no one ever admitted doing it, but only two of us live here.) Used this product on it, and it not only filled in where the chips were gone, it is a strong solid bond. Saved $500 for a new cooktop, and this one has character, too--so I tell my wife. This is a go-to product where superglue just won't cut it.

Ana Dulce Flores

My favorite epoxy

I have been using this product for many years and it has been extremely reliable. I have used it on wood, metal, and plastic. Mixed correctly it is the best available.

Maria Louise

Perfect solution for re-mounting kitchen solid surface sink.

Excellent product. I have a LG-HiMacs counter which is a Corian-type material. In it is a built-in double sink made of similar material. The sink is undermount and appeared to be glued to the nderside of the countertop, even with the sink opening of the counter (not recessed back like most undermount bath sinks, for example. The sink, after 10 years, started to separate from the counter and I needed a solution to glue it back up. The concern I had was that the sink has a hanging weight of over 40 lbs., not including a food disposal unit that adds at least 10 lbs. to that weight. I did a lot of research and decided that this Loctite Epoxy was the best solution. I received the epoxy/hardener kit and started my project. First I disconnected all plumbing and removed the disposal unit from one of the drains. I then pried the sink off of the counter which was much too easy; I guess the remaining glue was about to give way. Once the sink was removed I cleaned both the sink edge and the underside of the counter. Both appeared clean at the outset but did it anyway. I then roughed up both counter and sink glue points with a 150 grit sandpaper, wiped clean again with soapy water, rinsed with clean water and then everything was prepped. I should say I had to create aplatform of sorts under the sink that I could use to support the sink. This was simply a piece of plywood with 2 2x4's that were a bit longer than the bottom of the cabinet to the bottom of the sink one in place. I angled the 2x4 legs so the sink was lower while I applied the epoxy/hardener mixture then just brought them in closer together to raise the sink to the countertop. Warning, this stuff is messy and if it gets on you it will take days to pic off if you dont clean right away. I didnt have acetone like I thought i did so, it took me days. Once I applied the epoxy to the sink edge where it was to meet the counter, I raised the sink and adjust it to align perfectly with the sink hole opening. You have about 10 minutes to work the attached materials while the epoxy sets (from the time you mix the 2 compounds together) so plan this part out. It took me about 3 minutes after application of the epoxy to raise the sink and align it. I locked in the sink by wedging the 2x4 legs at the base of the cabinet below. 24 hours later, i started my cleanup of the sink, sanding away the excess epoxy with 80, 120 and 150 grit sandpaper then doing a final sanding with 220 grit sandpaper. I then wiped everything with a ScotchBrite soapy pad. No epoxy residue and the seal was very tight. I then removed the platform i created below to hold the sink while it cured. This was the scary part. Everything held though and it seemed very solid. I attached the disposal and all the plumbing and was done. Everything came out perfect and it looks great! I am glad I purchased this specific epoxy and it was worth every penny. I am confident it ill hold the 50 lbs. (the sink and disposal weight) as well as anything I place in the sink.